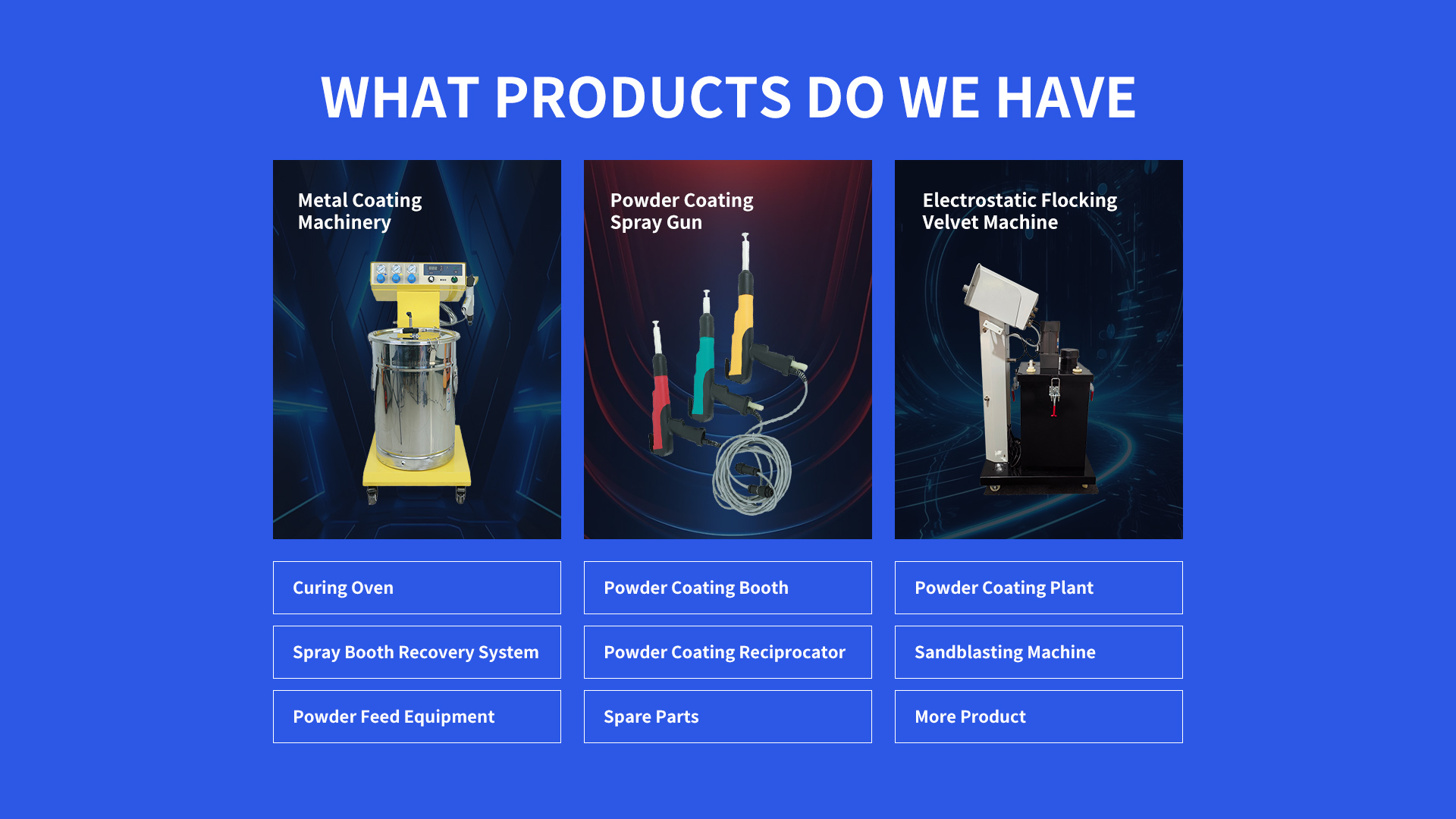

1. Manual Powder Coating Machine Overview and Components

Manual Powder Coating Machines For Sale are handheld or bench-mounted systems designed for small-scale or precision coating tasks. Key components include a spray gun, powder hopper, electrostatic generator, trigger mechanism, and grounding cable. Made from lightweight aluminum or durable polymers, these machines prioritize portability and ease of use while maintaining robust performance.

2. Applications of Manual Powder Coating Machines

These machines are ideal for automotive repair shops, custom metal fabrication, furniture restoration, and DIY projects. They excel in applying coatings to small parts, intricate designs, or low-volume production runs where flexibility and precision are critical.

3. Manual Powder Coating Machine Pricing

Prices range from 500forbasicmodelsto15,000 for advanced electrostatic systems with enhanced controls. Entry-level units suit hobbyists, while mid-range options (2,000–8,000) offer adjustable airflow and ergonomic designs. Customizations like extended warranties or upgraded nozzles add to costs.

4. Proper Use of Manual Powder Coating Machines

Ground the machine and workpiece to prevent static discharge. Adjust the powder flow rate (10–30 grams per minute) and voltage (30–80 kV) based on material type. Maintain a 6–12 inch spray distance for even coverage. Clean the nozzle and filter after each use to avoid clogs.

5. How to Choose a Manual Powder Coating Machine

Consider project size, powder type (e.g., epoxy, polyester), and desired finish quality. Opt for electrostatic models for complex geometries or manual guns for simplicity. Prioritize lightweight, ergonomic designs and check for certifications (e.g., CE, UL). Verify supplier support and warranty terms.

6. Safety Precautions for Manual Powder Coating Machines

Operators must wear NIOSH-approved respirators, gloves, and anti-static clothing. Work in well-ventilated areas to avoid inhaling fine particles. Ensure proper grounding to eliminate fire risks from electrostatic sparks. Store flammable materials away from the workspace.

7. Design Efficiency of Manual Powder Coating Machines

Modern designs focus on user-friendly operation and sustainability. Features like quick-release powder containers, adjustable triggers, and energy-efficient charging systems reduce downtime. Durable construction ensures reliability in demanding environments, while compact sizes save workspace.

8. Manual Powder Coating Machine Q&A

Q1: How often should manual powder coating machines be maintained?

A: Clean daily, inspect electrical components monthly, and replace nozzles annually for optimal performance.

Q2: Can manual machines apply multiple coatings in one session?

A: Yes, but allow proper curing time between layers to avoid defects.

Q3: Are manual powder coating machines energy-efficient?

A: Electrostatic models reduce powder waste by up to 50%, lowering material and energy costs.

Q4: What industries use manual powder coating machines most?

A: Automotive repair, artisanal metalwork, and small manufacturing businesses rely on them for custom projects.

Q5: How to troubleshoot uneven coating with a manual machine?

A: Check grounding, adjust powder flow, and ensure consistent spray distance.

This guide offers essential insights into manual powder coating machines for sale, empowering buyers to select equipment that enhances efficiency, safety, and finish quality for small-scale or specialized projects.

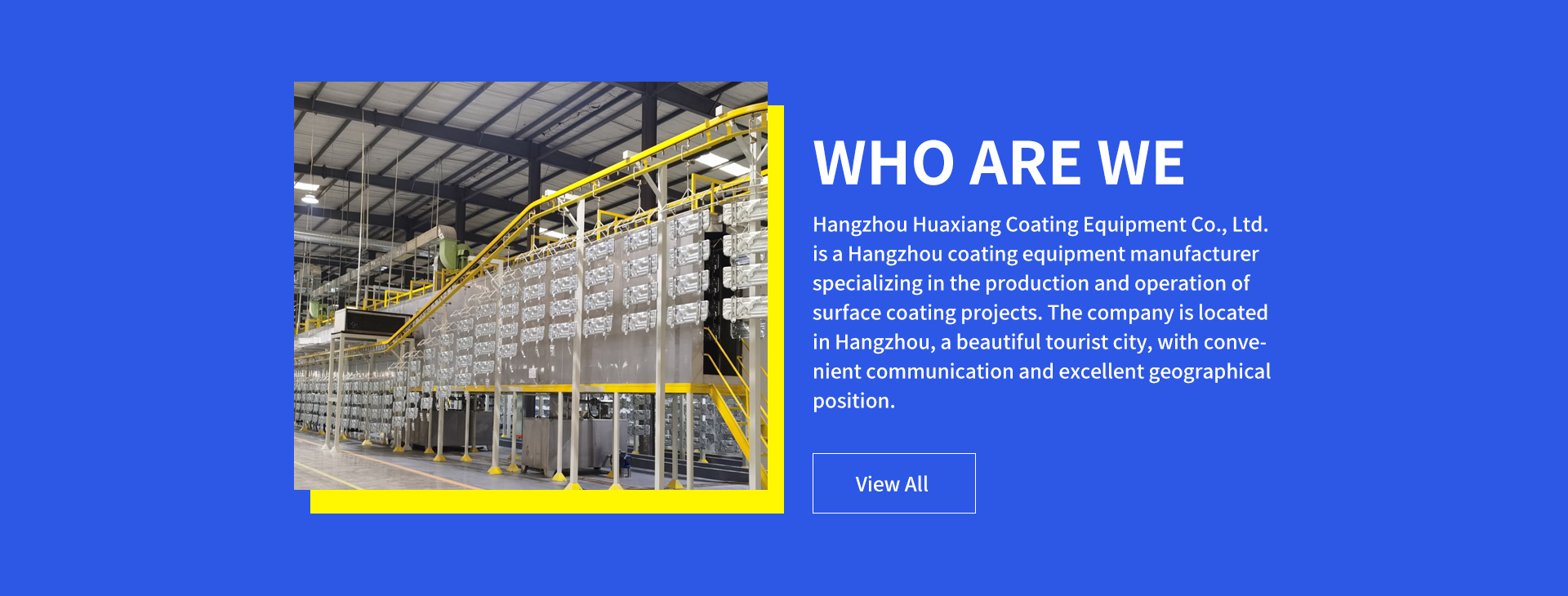

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com